Hello! My name is Erkin Oto, and I am a master`s student in Mechanical Engineering at Northwestern. I am working with Aaron Greco and Benjamin Gould on the In Situ Analysis of Laser Powder Bed Fusion Using Simultaneous High-speed Infra-red and X-ray Imaging project.

Laser powder bed fusion process is a type of additive manufacturing (AM) that selectively melt or bind particles in thin layers of powder materials to build 3D metal parts. However, the consistency of parts manufactured by this technique is still a problem, and overcoming this problem requires the understanding of multiple complex physical phenomena which occur simultaneously during the process.

Because the components are fabricated layer by layer, LPBF allows for the manufacture of geometrically complex parts that are not possible to manufacture with traditional manufacturing techniques. It also has the capability to make complex parts with significantly less wasted material than the other traditional manufacturing processes. However, the use of a high power laser beam leads to high temperatures, rapid heating/cooling, and significant temperature gradients resulting in highly dynamic physical phenomena that can form defects in the parts.

If the build parameters, including laser spot size, power, scan speed, and scan path, are not controlled, then the microstructure of the final product could contain unwanted porosity, cracks, residual stress, or an unwanted grain structure. It is essential that advanced in situ techniques, particularly those that can correlate material thermal conditions (i.e. heating and cooling rates, and thermal gradients) to build parameters, are required to be able to solve the unknowns of the process.

Although high-speed X-ray imaging provides great insight into the important sub-surface features that determine the quality of the LPBF process, it is unable to directly convey the quantitative thermal information that is necessary to fully understand the LPBF process.

Also, every industrial machine has some sort of IR camera attached to it. Therefore, if behaviors and defects seen in X-ray can be linked with IR videos, then the IR camera can be used within a control system to prevent defect formation.

The current project I am working on combines the high-speed infra-red (IR) imaging and hard X-ray imaging at the Advanced Photon Source (APS) at Argonne, to provide an analysis that correlates IR and X-ray images to be able to understand and quantify dynamic phenomena involved in LPBF. My work consists of observing the formation of multiple points of subsurface porosity, commonly referred to as keyhole pores. In specific, I am focusing on understanding the keyhole porosity formation at the end of each track which is referred to as the “end track keyhole porosity”. This phenomenon is especially of interest since under the same laser and material conditions, the end track porosity is not always observed. I am trying to shed light on the phenomena that are causing the random formation of these end track keyhole pores.

Figure 1: End track keyhole porosity formation

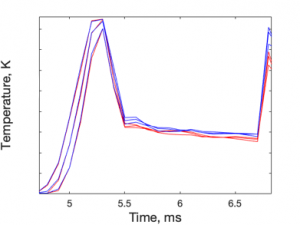

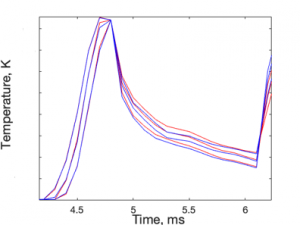

It was determined by my research group that there are large differences in the temperature history of the probed pixels when the experiments with and without the end track keyhole porosities are compared. It was also determined that a larger maximum cooling rate and a higher temperature after solidification was observed.

Therefore, I start by selecting a certain region of interest or the exact pixel on the IR images at the instant the end track keyhole porosity is observed on the X-ray image. This requires syncing the IR and X-ray images. After finding the right pixel, I look at the cooling rate of that specific pixel and compare it with the cooling rate of a pixel taken from an experiment done under same conditions and has not formed an end track porosity. The cooling rate comparison for the keyhole porosity formation is given below.

porosity formed no porosity

porosity formed no porosity

Figure 2: Cooling rate comparison for two builds, one forming an end of track porosity

The main advantage of this study is that combining the X-ray and IR imaging makes it possible to identify the thermal signatures that cause the formation of defects. This could further be developed by adding a control system in commercial printers that can identify defects in situ by tracking the thermal signatures of the build. The cost of the additive manufacturing processes could be cut significantly by determining a defect early in the process, so that the companies would not dedicate all the time and money later to find out that the built part is unusable after all.

References:

- Parab. et al. “Ultrafast X-ray imaging of laser-metal additive manufacturing processes.” Journal of Synchrotron Radiation, vol. 25, 2018, pp. 1467-1477.

- Cunningham. et al “Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging.” Science Mag, vol. 363, no. 6429, 22 Feb 2019, pp. 849-852.

- Zhao C. et al. “Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction.” Nature Research Journal, vol. 7, no. 3602, 15 June 2017

This is very interesting, You are a very skilled blogger. I have joined your feed and look forward to seeking more of your great post. Also, I’ve shared your site in my social networks!|